1600i Hydraulic Tappets Information

Common Hydraulic Tappet Problems:-

A common problem with the 1600i

engine is rattling hydraulic tappets, especially after the car has not been

driven for a few days.† This could be

caused by any of the following:-

-

Engine stood idle for a few days

(about 2 days or longer).

-

Incorrect Oil Type/Grade.† Use 15W40

mineral engine oil only !!

-

Oil level too low !!† Top up the oil level, but never overfill it !!

-

Sludge within the engine oil.

-

Air present within the hydraulic

tappets themselves (e.g. air inside its piston)

The following sections will attempt

to explain how to stop the hydraulic tappets from rattling.

Drive the Car!:-

The first simple solution to this

problem is to simply drive the car carefully for about 15 minutes.† The engine should have stopped rattling by

then.

Flush Out the Sludge Within the

Engine:-

If the engine has not stopped

rattling after it has warmed up (after about 15 minutes) then the engine may

have sludge within its own oil.

To remove the sludge, do the

following:-

-

At 200 miles (300 km) before the

next service is due, add some liquid molybdenum disulphide (e.g. Liquid Moly)

to the engineís own oil.

-

Drive the car normally for the next

200 miles (300 km).

-

Flush out the engine with engine

flush and change the oil.

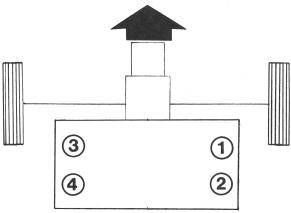

Increase the Oil Flow:-

The oil flow-rate can be increased

by turning out the very large cheese-headed bolts on the bottom of the

crankcase.† These are located on the

left hand side of the crankcase.† The

front one is next to the gearbox and the rear one is next to the oil filter.

Another possible solution is to

replace the oil pressure relief valves (this problem is rare).

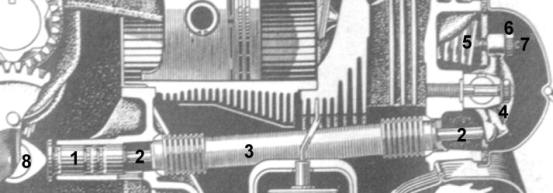

††††††††† Front oil pressure relief valve††††††††††††††††††††† Rear oil pressure relief valve

Caution! Make sure that

you do not increase the oil flow-rate by too much otherwise oil may

†††††††††††††† leak through the engineís gaskets !!

Remove the Air from the

Hydraulic Tappets (last resort !):-

If the above did not work, then there may be air present

within the hydraulic tappets.† This will

require the engine to be removed from the car and its crankcase split.† This is not for the faint-hearted !!

To check to see if there is air present within the hydraulic

tappets, do the following:-

-

Unclip the rocker covers and remove them

-

Push down on each of the rocker arms where they connect to

the push rods within the cylinder heads.†

The rocker arms should not move under heavy thumb pressure.† If any of them do then those tappets will

have air present within them.

Use heavy thumb pressure on these parts of the rocker arms.

![]()

If air is present within any of the tappets, then do the

following:-

-

Remove the engine from the car (see the Engine Removal and

Re-Installation section for further information).

-

Remove the distributor.†

(Make sure that you mark up both the distributor and the crankcase with

a marker pen.† This will help you to

re-install the distributor back into itís correct position).

-

Remove the distributor gear.† Be careful that you do not damage it during the process !

-

Remove the crankshaft pulley wheel.

-†††† Remove the clutch and flywheel.† The flywheel its self will be very

tight.† Use a

††††† very large torque wrench, a long bar and

a flywheel locking tool to undo the

††††† flywheel nut.† Be careful that you donít hurt yourself !!

-

Split the crankcase.

-†††† Remove the camshaft from the

crankcase.† The hydraulic tappets should

now be

††††† accessible.

To remove air from the tappets, do the following:-

-

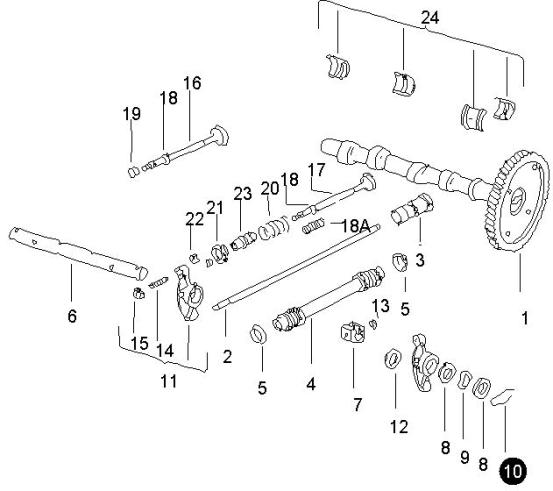

Pry off the circlup (1) from the top of the hydraulic

tappetís piston.

-†††† Remove the pushrod end of the piston (2),

the piston itís self (3) and its spring,

††††† etc . (items 4 to 7).

-

Now fill up the tappet with engine oil via the tappetís

lateral drilling (8) whilst the tappet is upright.

-

Re-assemble the hydraulic tappet, which is done by doing the

following:-

-†††† Use an old pushrod and saw one end of it

off.

-†††† Now put the hydraulic tappet and the

sawn-off pushrod into a vice.†

††††† When you are re-assembling the tappet,

make sure that the ball (4) is located

††††† in the cup (6) is located correctly as

shown below.† You may need a piece of

††††† wire or a very small screwdriver to do

this.

-††††

Slowly do up the vice to push the hydraulic tappet back

together.†

††††† Replace the circlip once the hydraulic

tappet has been squeezed up together.

-

The hydraulic tappet should now be ready for use and can be

put back into the

††††† engine.

Exploded view of a hydraulic

tappet:- 1.†† Circlip 2.†† Pushrod End 3.†† Piston 4.†† Ball 5.

Small

Spring 6.

Cup Washer 7.

Large

Spring 8.†† Tappet Housingís (Laterel) Oil Drilling

If the hydraulic tappet is badly worn out or damaged then it

must be replaced !!

Hereís what a real 1600I hydraulic tappet looks like:-

Circlip Pushrod end Bearing ? Piston Spring Hydralic Tappet Housing

Full exploded

views of a 1600i hydraulic tappet

After all of the hydraulic tappets have had the air removed

from them, then the following should be done:-

-

Re-install the camshaft in the crankcase

-

Re-assemble the crankcase

-

Re-assemble the clutch, flywheel and crankshaft pulley

-

Re-install the engine back into the car

-

The hydraulic tappets should now be left to settle for at least 10 minutes before you do

anything else.

After the hydraulic tappets have been settled, the

adjustment of them must now be checked.

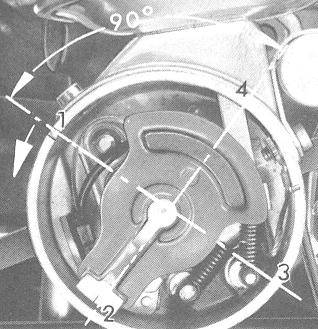

Checking the firing-point of

each cylinder.† The rotor arm should

line up with the notch on the distributor when cylinder 1 is at itís

firing-point. Note the direction of the arrow

!† This is the direction that you

should move the engine with a ratchet and socket. Note: This is

not a real 1600i ††††††††† distributor but an old ††††††††† carburettor-based one.

Distributor Ė Inner View

First of all move the crankshaft until the number 1 cylinder

is at itís firing-point.† A good way of knowing

when it is at itís firing point is to look at the rotor arm inside the

distributor as shown below:-

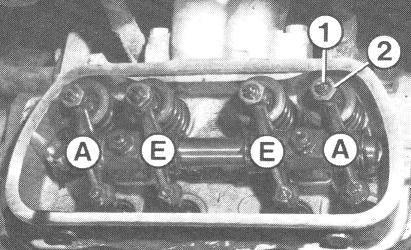

The inlet and exhaust valves for the number 1 cylinder can

now be adjusted.† The photo below shows

the layout of the cylinder head:-

Cylinder Head (Inner View) 1 = Adjustment Screw 2 = Locking Nut A = Exhaust Valve †††††† (AuslaŖventil) E = Inlet Valve ††††† (EinlaŖventil)

Adjust cyllinder oneís exhaust (A) valve.† Slacken the locking nut (2) and turn the adjustment

screw (1) until the screw just touches the rocker arm.† Now tighten that screw by a further 1 Ĺ

turns and tighten-up the locking nut.†

Make sure that the adjustment screw does not rotate when you tighten-up

the locking nut !!

Repeat the same procedure for number one cylinderís inlet

(E) valve.

Now rotate the engine until cylinder 2 is at itís firing

point.†

Note:†† There are no markings on the distributorís housing for cylinders 2, 3 and

4.†

††††††††††† Use a protractor

and a marker pen to mark up the firing points of cylinders 2, 3 and 4.

††††††††††† These

will be at 90į away from each other.

Repeat the same procedure for cylinder 2.

Repeat the same procedure for cylinders 3 and 4.

After the hydraulic tappets have been adjusted, re-install

the rocker arm covers and the engine should not rattle anymore.

Overall Engine View Diagram:-

Gearbox

Engine

|

Gearbox |

|

Engine |

Engine (Cross-Sectional View):-

Hydraulic Tappets Items:-

1 = Hydraulic Tappets††††††††††††††††††††††††††††††††††††††† 5

= Valve Stems

2 = Push Rods††††††††††††††††††††††††††††††††††††††††††††††††† 6

= Locking Nuts

3 = Push Rod Tubes††††††††††††††††††††††††††††††††††††††††† 7

= Adjustment Screws

4 = Rocker Arms†††††††††††††††††††††††††††††††††††††††††††††† 8

= Camshaft

Engine Parts List:-

Parts List

Item†††† VAG Part #†††††† Description††††††††††††††††††††††††††††††††††††††††† Quantity

Required

3† ††††††† †043 109 309†††† Hydraulic

tappets†††††††††††††††††††††††††††††††††††††††††††††† 8

2†† †††††† 113 109 301 E † Push Rods F > > 11-T-021 008†††††††††††††††††††††††††† 8

2†† †††††† 043 109 301†††† Push Rods F 11-T-021 009> >††† ††††††††††††††††††††††††† 8

4 †††††††† 113 109 337

A†† Push Rod Tubes††††††††††††††††††††††††††††††††††††††††††††††† 8

5†† †††††† 113 109 345 A† Hydraulic tappet seals†††††††††††††††††††††††††††††††††††††††† 16

This document was translated into english (in my own words

from what I have understood of it) by myself, Phil Ade on Tuesday 14th

March 2006.†

This documentation has also been updated on Tuesday 17th

April 2007 by Phil Ade.

The original german documentation is on the 1600i website (www.1600i.de)

in various sections.